The Real Cost of Equipment Ownership — and Why Renting Sometimes Makes More Sense

Everyone loves the idea of owning their own equipment… until reality sets in.

It’s easy to justify buying a telehandler, rough-terrain forklift, or aerial lift when you’re busy and want your own equipment on site.

The math looks simple: “Why rent for $2,000 a month when I can own it and pay nothing later?”

And when a dealer says they’ve got a great deal on a new scissor lift or telehandler, it sounds like a no-brainer — until the real costs show up.

What most people don’t factor in are the hidden costs — maintenance, inspections, fuel, downtime, parts, and insurance.

Machines aren’t like land or buildings that appreciate over time. They depreciate every year you own them, and the older they get, the more they cost to keep running.

At Xtreme Pro Services, we see both sides every day — the owner who’s proud of their fleet and the one who wishes they’d rented instead.

Here’s why that “great deal” on a used scissor lift, telehandler, or boom lift can sometimes end up costing far more than a rental ever would.

1. Every Machine Breaks — It’s Just a Matter of When

There’s no such thing as a piece of equipment that runs flawlessly forever.

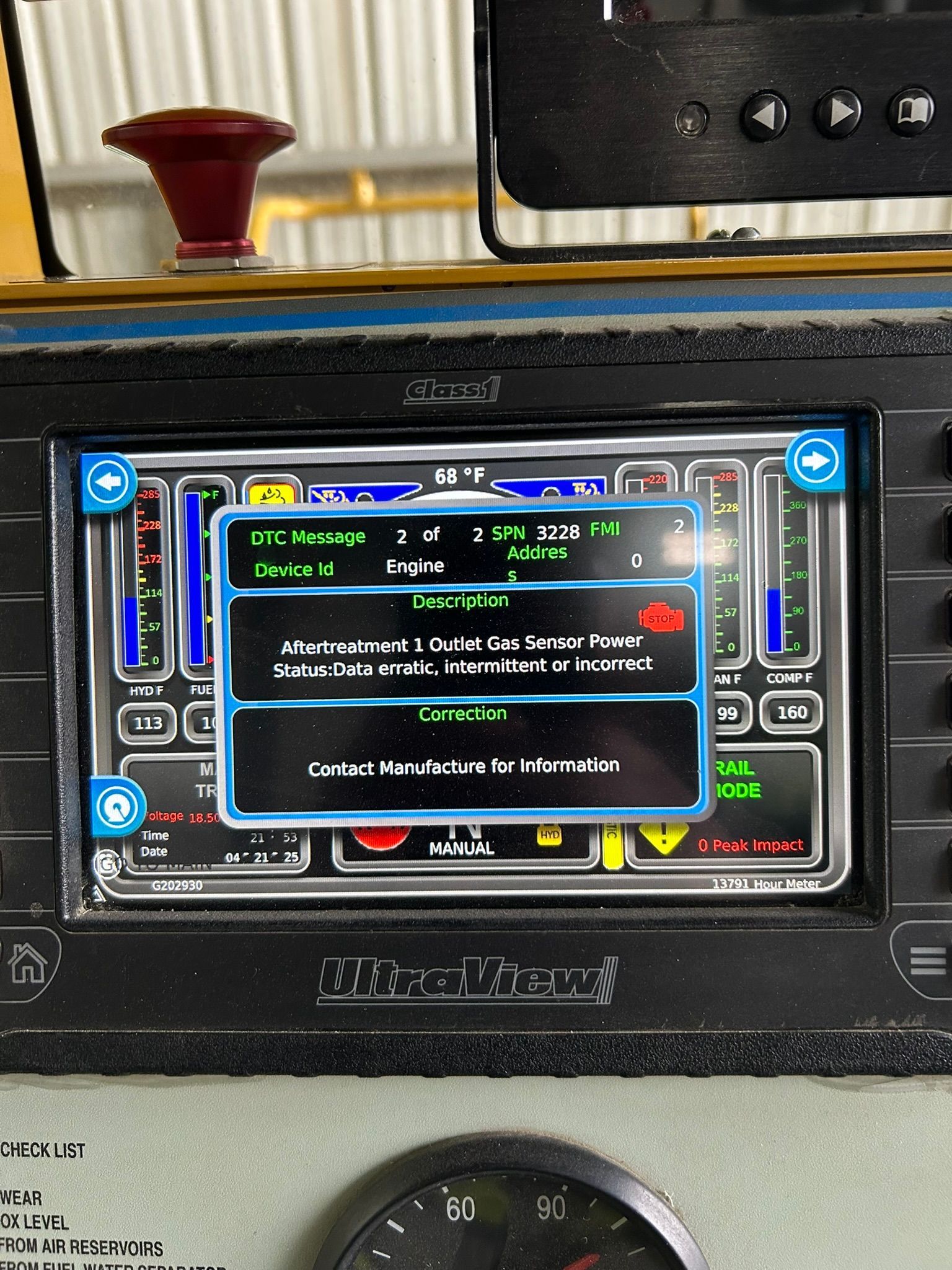

Even the best-maintained machines have wear components — hoses, seals, filters, sensors, and controllers — all designed with a service lifespan.

Hydraulic leaks, dead batteries, cracked tires, or software faults don’t ask what your schedule looks like. They happen when they want to — usually right in the middle of a project.

That’s the reality of owning heavy construction equipment: you don’t just own the machine — you own every problem that comes with it.

Whether it’s an outdoor aerial lift working in cold North Dakota winters or an indoor electric scissor lift used in a warehouse, everything mechanical will eventually need repair, calibration, or service diagnostics.

2. The Hidden Costs of Ownership

Cost Type

- Preventive Maintenance

- Repairs & Diagnostics

- Storage & Transportation

- Downtime Costs

- Depreciation

Example

- Filters, fluids, hoses, inspections

- Controllers, sensors, hydraulics

- Trailers, insurance, permits

- Lost production, rental replacements

- Machine losing value every year

Here’s what most buyers forget to include when they “do the math” on equipment ownership:Even if you turn your own wrenches, parts and fluids add up fast.

A single controller or hydraulic pump failure on a

JLG aerial lift or

Genie telehandler can cost more than a month of rental.

And while your equipment sits waiting on parts or a technician, the job doesn’t stop — but your costs keep climbing.

That’s the hidden side of

owning vs renting construction equipment that most buyers don’t think about until it’s too late.

2.1 Cost per Hour — The Real Way to Measure Ownership

The smartest way to compare owning versus renting isn’t by the purchase price — it’s by the true cost per hour to operate.

That number includes every operating and ownership expense:

- Fuel and DEF for diesel units

- Maintenance, filters, and grease points

- Tires, batteries, or tracks

- Repairs and diagnostics

- Shop labor or mobile service calls

- Insurance and storage

- Downtime and depreciation

When you divide your total annual ownership costs by the actual working hours, the truth becomes clear.

For example, a rough-terrain forklift that costs $50,000 might seem like a steal — but after adding $8,000 a year in maintenance, $4,000 in parts, $2,000 in insurance, and $6,000 in downtime, the real cost per hour can easily exceed what a rental company charges.

That’s why large contractors and industrial operators across North Dakota and Montana track cost per hour closely — it’s the only accurate way to see what equipment ownership really costs.

2.2 Utilization — Are You Really Going to Use It Enough?

Even if you know your cost per hour, you still have to ask the big question:

Are you going to use the equipment enough to justify owning it?

A telehandler, aerial lift, or scissor lift that only runs a few hundred hours per year will have an extremely high cost per hour once you include insurance, maintenance, and depreciation — because those expenses don’t stop when the machine does.

Rental companies stay profitable because their machines are always working.

Most private owners can’t keep that same utilization level.

That means their machines sit idle, batteries fail, hydraulic seals dry out, and systems corrode from disuse — all while the value keeps dropping.

If your work is seasonal or inconsistent, renting or leasing almost always makes better financial sense than owning.

3. The “Perfect Machine” Myth

A lot of owners expect their boom lift or scissor lift to perform the same ten years down the road as it did brand new.

That’s not realistic — and it’s not how mechanical systems work.

Electrical boards age. Hydraulic seals harden. Sensors drift out of range.

Every hour on the meter is one step closer to repair — and no brand is immune.

When something fails on a rental machine, it’s the rental company’s responsibility.

When it fails on your own machine, it’s your downtime, your repair bill, and your lost production.

4. Depreciation — The Cost Nobody Talks About

Equipment doesn’t hold value like real estate.

They’re not like buildings or land that appreciate over time — they depreciate with every hour and every start-up.

A new telehandler, rough-terrain forklift, or aerial lift loses 20–30% of its value the moment it leaves the lot.

After five years, even with great care, you’ll get half or less of what you paid — and that’s if the market’s good.

If you need to upgrade or sell during a slow season, you’ll often lose even more.

Rentals don’t depreciate in your books. You pay for what you use and walk away — no long-term liability, no resale hassle.

5. Maintenance Isn’t Optional — It’s Inevitable

Too many owners think maintenance is something they’ll “get to later.”

But machines don’t wait. Ignored filters clog pumps. Low hydraulic oil takes out motors.

Deferred maintenance turns small issues into major failures fast.

That’s why professional rental fleets stick to strict service schedules — they know when repair hours start costing more than the unit’s value.

A neglected machine, even for one season, can cost thousands to bring back into spec.

Rental units, on the other hand, are fleet-maintained and inspected regularly — ready to go when you need them.

5.1 Break-In Maintenance — The First Hidden Bill

Even a brand-new scissor lift or telehandler isn’t maintenance-free. Most manufacturers require a break-in service within the first 100–250 hours to keep the warranty valid.

That service is almost never covered under warranty — it’s the customer’s responsibility to pay for it.

It typically includes changing all fluids and filters, torquing hardware, checking valve settings, and verifying software calibration.

Skipping that first service can void the warranty entirely, and many owners don’t find out until a claim gets denied.

So even fresh off the dealer lot, there’s already a hidden cost of ownership — and it hits within the first few months.

6. When Owning Makes Sense

There are times when ownership does make financial sense:

- You use the machine full-time on your own jobs.

- You have skilled in-house mechanics and diagnostic tools.

- You have storage and controlled conditions to reduce wear.

- You plan to keep it for years and manage depreciation strategically.

If you can check those boxes, ownership can absolutely pay off — especially if you buy smart, maintain well, and use OEM-level diagnostic tools like we do at Xtreme Pro Services.

7. When Renting Is the Smarter Play

If your usage is seasonal, part-time, or low-hour, renting is usually the smarter move.

You only pay for what you use. You don’t deal with breakdowns, repairs, insurance, or resale.

And you can always get the exact size or model for each job — whether that’s an indoor electric scissor lift or an outdoor 4x4 rough-terrain telehandler.

Many rental companies even offer “low-hour rental” programs.

That doesn’t mean the machine has low hours — it means you won’t be putting many on it.

These are well-maintained, higher-hour machines rented at deeply discounted rates for customers who only need a few hundred hours per year.

In most cases, you couldn’t own, maintain, and insure a comparable machine for what these rental programs cost.

They’re perfect for small contractors, ag operations, and energy sites that need reliable equipment occasionally without full ownership overhead.

7.1 Be Smart — Don’t Let a Sales Pitch Make the Decision

It’s easy to get excited when someone offers you a “great deal on a new scissor lift or telehandler.”

But remember — a salesman’s job is to move iron, not manage your bottom line.

That’s why it pays to do your own research, run your own numbers, and make your own decision before signing anything.

Dealers will highlight low financing and “equity ownership,” but they rarely mention:

- The inspection and maintenance costs not covered by warranty.

- Diagnostic software fees and labor after the first year.

- The downtime waiting on OEM parts or factory support.

Don’t let a short-term deal turn into a long-term liability.

Calculate your true cost per hour, your expected utilization, and your cash flow impact before you buy.

If the math doesn’t work, walk away — no matter how good the pitch sounds.

8. The Xtreme Pro Services Perspective

We maintain and repair hundreds of machines across North Dakota and Montana, and we see the same pattern every year:

Owners underestimate how much time and money it takes to keep a single piece of heavy equipment safe, reliable, and compliant.

That’s why Xtreme Pro Services helps equipment owners, rail yards, and contractors make smarter choices about when to rent, when to buy, and how to protect their investment.

If you’re thinking about purchasing a telehandler, rough-terrain forklift, or aerial lift, we can help you:

- Estimate real maintenance and ownership costs.

- Review service records and diagnostics.

- Evaluate whether the ROI beats renting.

A few hours of planning can save you thousands — and keep your operation productive year-round.

Think Before You Buy — Let Data, Not Emotion, Make the Decision

701-987-9877

xtremepro.services

Serving Williston, Tioga, Watford City, Sidney, Minot & surrounding areas

Xtreme Pro Services — North Dakota’s trusted name for aerial lift, telehandler, and rough-terrain forklift repair, diagnostics, and service.