If That Fuse Is Blowing — Stop Replacing It With a Bigger One

“When you keep putting in bigger fuses, you’re not solving the problem — you’re just delaying the disaster.”

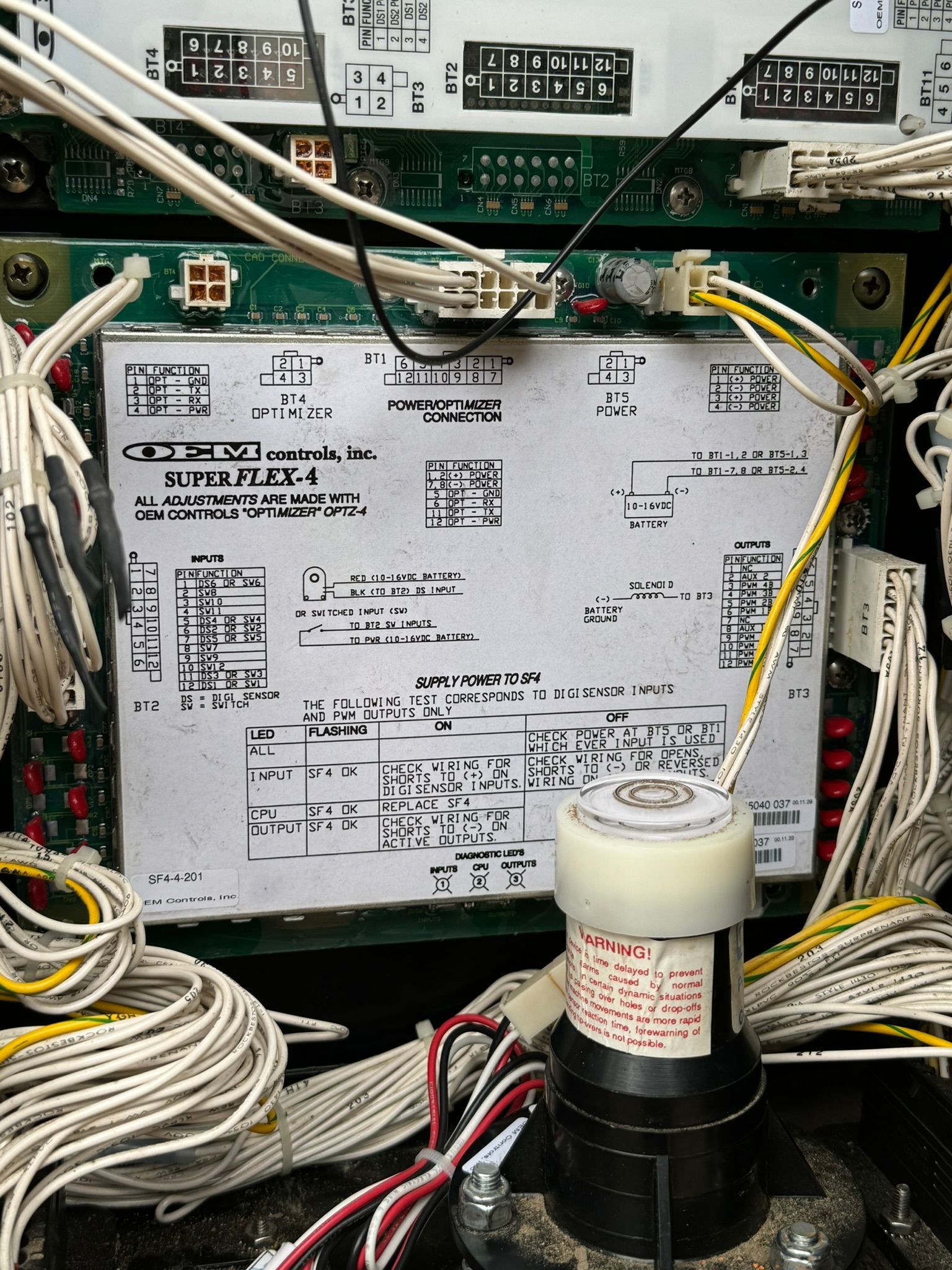

At Xtreme Pro Services, we see it all the time: a boom lift, telehandler or forklift keeps popping a fuse. The operator or technician just swaps in a larger-amp fuse and sends it back out.

But here’s the truth: the fuse is doing its job. It’s blowing for a reason — a short circuit or high resistance — and ignoring it means you’re gambling with wiring, modules, relays, and your budget.

Instead of bigger fuses, we use proper diagnostics tools — like the Mac Tools ET8017 Fuse Saver — to find the root cause and fix it once, right.

1. How a Simple Fuse Circuit Works

Let’s break down a typical 12V-24V DC circuit in your equipment:

- Battery → Fuse → Wiring → Load (motor, valve, sensor) → Ground

- The fuse sits right after the power source to protect the wiring and components from excess current.

- If the current exceeds the fuse rating due to a short or heavy load, the fuse element melts and opens the circuit. This prevents wiring from overheating, insulation from melting, or modules being damaged. (See explanation of fuse functioning)

- Important detail: The fuse rating is chosen based on the continuous current of the load plus a safety margin — not arbitrary.

- If you replace a blown fuse with a larger one, you’re changing the safety device so it no longer protects the circuit correctly. Instead of the fuse blowing, the next weakest link becomes wiring or components — and they might burn or fail.

🔍 Key takeaway: A fuse blow = signal. A bigger fuse = ignoring the signal.

2. Why Fuses Blow — Short vs High Resistance

Short circuit

- A hot wire or bare conductor touches ground, battery positive connects directly to ground through very low resistance.

- The current spikes far above the fuse rating and blows it quickly.

High resistance fault

- A wiring circuit has loose connection, corroded terminal, damaged wire, or partial short.

- Current stays high, maybe near fuse rating, heat builds, insulation gets hot, fuse may blow eventually.

- Even if the fuse holds for a while, the wiring is still compromised — insulation damage, connector corrosion, intermittent faults.

In each case, simply installing a larger fuse doesn’t fix the fault. It just removes the weakest “safety link” and places the rest of the circuit at risk.

3. The Right Way: Diagnosing the Fuse-Blowing Circuit

These combine the toughness of solids with the comfort of pneumatics — made of solid rubber but shaped like air tires.

Here’s how we handle a fuse-blow problem at XPS:

- Remove the fuse, inspect the blown fuse type and amperage.

- Install a fuse saver tool (such as the ET8017) in place of the fuse. This gives us a resettable breaker rather than single-use fuse.

- With the fuse saver installed, activate the circuit and begin stress testing: wiggle wiring, watch harnesses, monitor current draw, feel for heat.

- Identify where current spikes or drops, isolate wiring segments, check ground paths and connectors.

- Once fault is isolated (short to ground, corroded connector, slipped loom, damaged component), repair or replace the part.

- Replace with correct fuse rating per OEM specification. Test again.

- Document the repair and verify no further fuse blows under normal use.

Using the fuse saver saves time, money (you’re not buying fuse after fuse), and protects components during diagnostics.

4. Common Mistakes We See

- Using next-higher fuse rating: e.g., circuit spec 20A, fuse blows → install 25A. Result: wiring may carry 25A continuously, overheat.

- Uninspected wiring after fuse blow: conductor may be damaged, insulation melted, connector burnt — simply replacing fuse ignores that damage.

- No current draw test: Just swapping fuse ignores that the load may now draw too much current due to internal fault.

- Ignoring ground paths: Poor chassis ground or connector cause high resistance and overheating, fuse may blow.

5. When to Replace vs. Repair

Replace fuse: Only after the fault has been located and repaired, and you install the exact spec fuse.

Repair circuit: When fuse keeps blowing, or replaced fuse blows again — this indicates underlying fault.

Replace fuse rating? Not unless OEM changed it during service bulletin — never just because it keeps blowing.

6. The Bottom Line

That fuse is not your enemy — it’s your helper.

If you keep putting in a bigger fuse, you’re ignoring the root problem — and risking expensive wiring, equipment failure, or downtime.

At XPS, our diagnostics go beyond replacing fuses. We identify the real fault, repair it, and restore the circuit to OEM spec.

With tools like the fuse saver, we protect your equipment and your budget.

Need Professional Circuit Diagnostics?

If you’re dealing with recurrent fuse-blowing, blown fuses under load, or intermittent electrical faults on your aerial lift, telehandler or forklift — we can help.

📞 701-987-9877

🌐 xtremepro.services

📍 Serving Williston • Tioga • Watford City • Sidney • Minot

Xtreme Pro Services — Precision Diagnostics. Electrical Reliability.