Why Proper Electrical Connectors Matter — and Why We Don’t Use Butt Splices

Because good electrical work isn’t about making it work — it’s about making it last.

If you’ve ever traced down a wiring problem on a piece of equipment only to find a handful of mismatched connectors, heat-shrink splices, or wire nuts — you know the frustration.

It’s one thing to make a circuit work again.

It’s another to make it work reliably, safely, and serviceable down the road.

At Xtreme Pro Services, we don’t patch electrical problems — we restore them to factory standards using the same Deutsch, Weather Pack, and OEM-style connectors that the machine was built with.

Because the goal isn’t just to get the machine running today — it’s to make sure the next technician can diagnose it tomorrow.

1. The Problem With Quick Fixes

A “butt splice and tape” might get a machine moving again, but it comes with hidden costs:

- Poor sealing: Moisture creeps in and corrodes the wire from the inside out.

- Weak mechanical strength: Vibration loosens the crimp over time.

- No strain relief: The wire breaks at the splice under flexing.

- Hard to trace later: Mixed connectors, tape, and colors make diagnostics confusing.

- Non-OEM appearance: It signals cut corners and reduces resale value.

In harsh environments like North Dakota and Montana, where machines face dust, snow, and daily vibration, a poor splice might last weeks — but not seasons.

Electrical failures are one of the top causes of intermittent faults in aerial lifts, telehandlers, and rail movers.

We see it all the time: a “ghost code” that turns out to be corrosion inside a crimp or a melted connector that was never sealed properly.

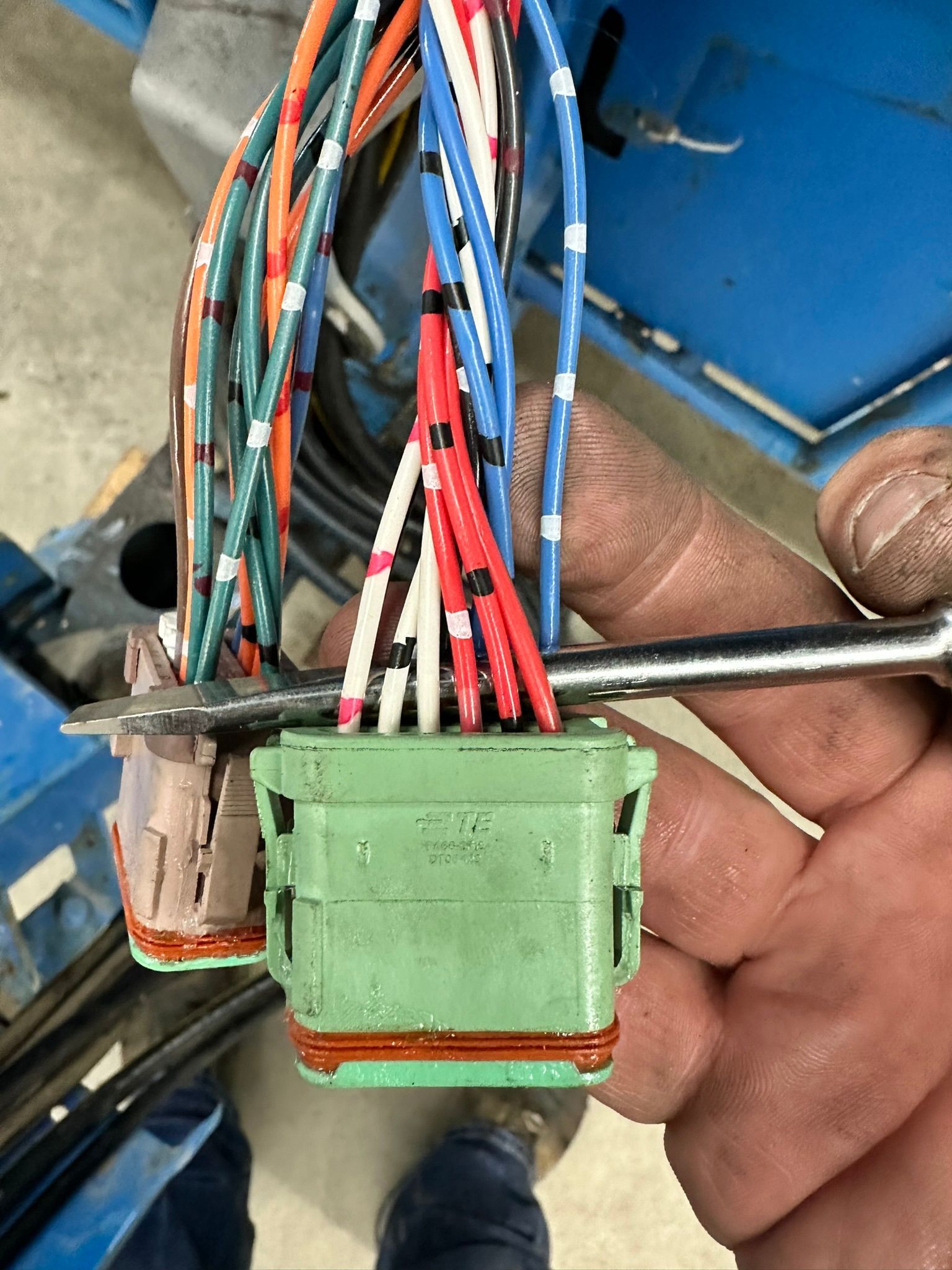

3. The Right Way: OEM-Grade Connectors

We stock and install OEM-spec connectors on every job — including:

- Deutsch DT, DTM, and DTP series for sealed multi-pin connections.

- Weather Pack and Metri-Pack for light- and medium-duty harnesses.

- AMP/Tyco connectors for control systems and module wiring.

- OEM pigtails for brand-specific replacements (Genie, JLG, Skyjack, CAT, etc.).

Each connector includes:

- Proper wire seals and cavity plugs

- Crimped terminals using ratcheting crimpers

- Dielectric grease application for corrosion resistance

- Connector boots or loom protection for abrasion control

This is how manufacturers build them — and it’s how we fix them.

3. Why It Matters for Diagnostics Later

When wiring is repaired correctly, future diagnostics become faster and more accurate.

Proper connectors:

- Maintain consistent wire colors and pinouts.

- Allow other technicians to use OEM diagrams without guessing.

- Keep CAN communication and sensor signals clean and stable.

- Prevent false fault codes from voltage drop or signal noise.

It’s the difference between spending 15 minutes diagnosing a lift — or wasting hours chasing false readings caused by corroded splices.

Clean, consistent

electrical work is a

professional courtesy to whoever touches that machine next — including you.

4. The Enemies of Good Electrical Work

Moisture, dirt, and vibration destroy wiring faster than anything else.

When water gets inside a connector or splice, it starts a slow corrosion process that travels under the insulation.

Even if you can’t see it, the wire becomes brittle, resistance increases, and voltage drops under load.

In freezing weather, trapped moisture expands inside connectors, pushing terminals apart and breaking contact.

That’s why sealed connectors — with silicone seals, cavity plugs, and dielectric grease — are not optional in outdoor and off-highway applications.

They’re mandatory if you want reliability.

5. Real-World Example

We were called to diagnose a boom lift with repeated “tilt sensor open circuit” codes.

A previous repair had been made with three butt splices wrapped in electrical tape, buried under the platform.

Moisture had wicked into the wires, corroding the strands all the way up to the main harness.

We rebuilt the section using proper Deutsch DTM connectors, heat-sealed boots, and factory-style loom.

The codes cleared — and the voltage drop disappeared.

That’s the difference between fixing it and fixing it right.

6. Why a Professional Carries Connectors — Not Just Wire and Tape

A top-tier mobile service technician doesn’t just bring tools — they bring solutions.

That means:

- Carrying full connector kits for Deutsch, Weather Pack, and OEM types.

- Having crimpers, seal tools, and cavity plugs for every situation.

- Stocking spare terminals and wire sizes for both low-current sensors and high-current actuators.

- Keeping heat-shrink, loom, and dielectric grease on hand.

Anyone can twist wires together.

A professional restores the circuit exactly as it left the factory — sealed, labeled, and dependable.

7. The Bottom Line

Electrical systems are the nervous system of your machine.

Poor repairs cause long-term headaches, wasted money, and endless diagnostic confusion.

At Xtreme Pro Services, we fix wiring the right way — using the same Deutsch, Weather Pack, and OEM connectors your machine was built with.

Every repair is sealed, tested, and documented — because the goal isn’t just to make it work, it’s to make it last.

If your machine is throwing fault codes, losing power, or showing intermittent errors, it might not be the module — it might be the connector.

Need Electrical or Wiring Repair Done Right?

From simple connector replacement to complete harness rebuilds, we have the tooling and expertise to do it right the first time.

701-987-9877

xtremepro.services

Serving Williston • Tioga • Watford City • Sidney • Minot

Xtreme Pro Services — OEM-Level Diagnostics. Factory-Grade Repairs.